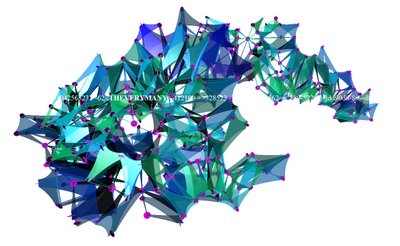

THEVERYMANY (Marc Fornes, Skylar Tibbits) has been kindly invited to exhibit a physical piece at

"Generator.X v2.0: Beyond the screen" - a workshop and exhibition about digital fabrication and generative systems curated by Marius Watz (http://www.generatorx.no/) in collaboration with Club Transmediale and [DAM] Berlin.

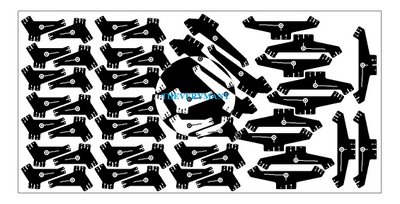

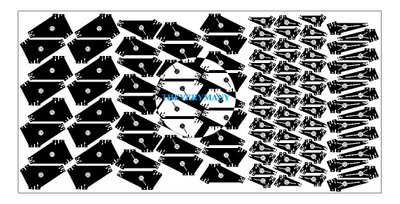

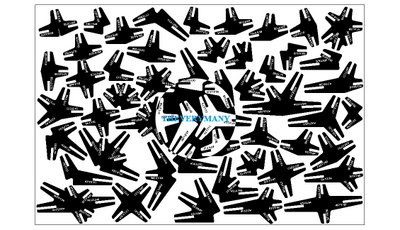

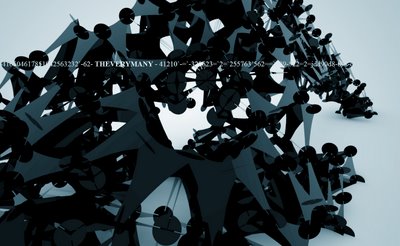

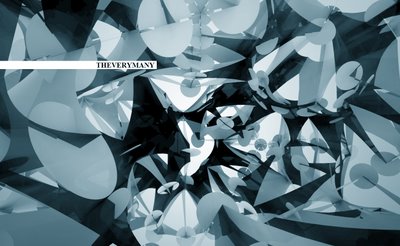

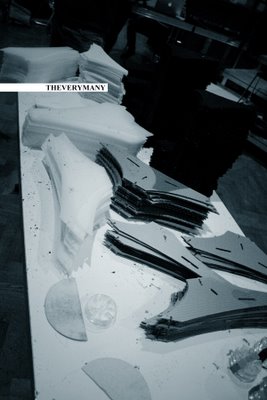

Based onto earlier experimentation (Aperiodic series) the installation is an assembly of nearly 500 flat panels (11 types) all milled within 6 sheets (8 feet by 4 feet) of corrugated plastic (4 colors: black, silver grey, white and translucent) and also nearly 500 assembly details (moreless all unique!) all laser cut onto 7 sheets of transparent acrylic...

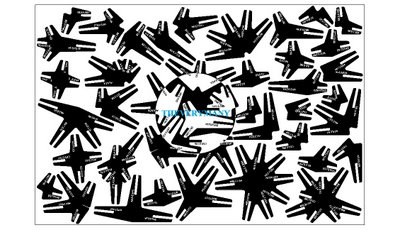

Despite mesuring 13 feet long (after been scaled nearly by half for simple reason of space available within the gallery!) all the panels and assembly details are now flying over nested within one suitcase only...

(pictures of the assembly process should come up soon)

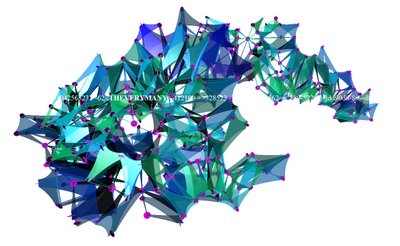

It has been quite some intense moments of scripting since last weekend - mainly sequences of utilities codes - in order to perform a complete automaton starting from the first 4 nurbs curve (those ones were drafted!), the generation of the geometries till the production of each components, notches, unroll, color coding, naming, etc... but there were also a lot of discussion on logic, sequence and protocols to be set up in order to PRE-facilitate as much as we can the entire physical re-fold-assembly of nearly a thousand parts...

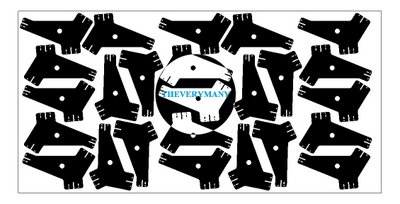

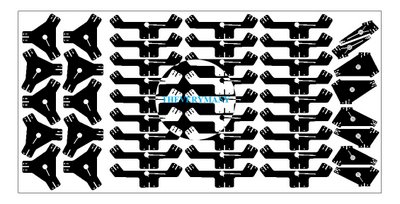

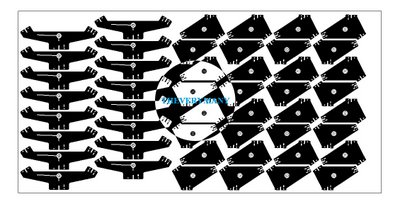

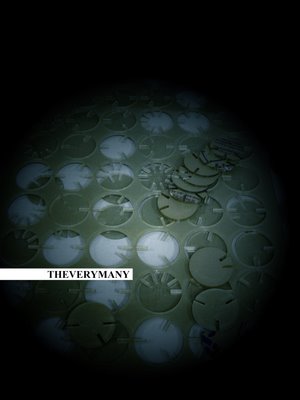

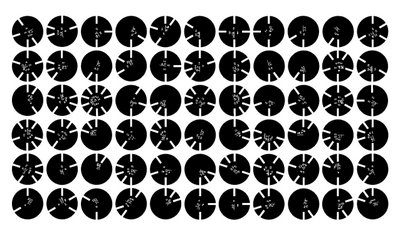

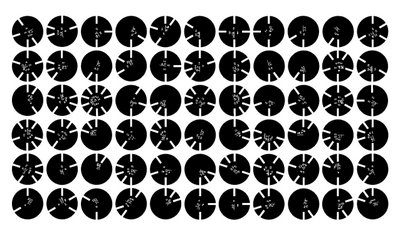

Illustrated above (top) the layout of one of the acrylic sheet (number 6) with 66 assembly details - all got named with the number of the piece (as text + name of the object) + each notche with the color of the brick it should connect to and the name of its panel it should locked in...

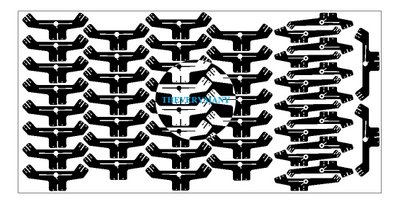

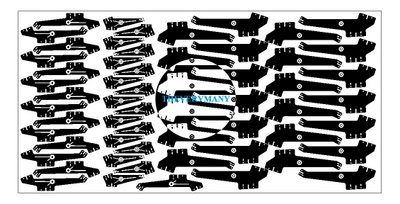

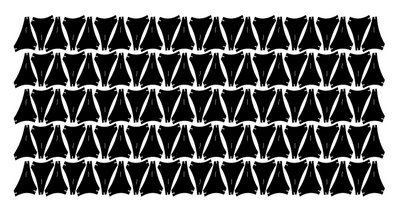

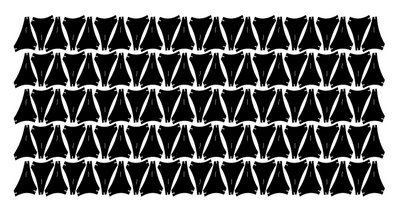

Illustrated above (bottom) the lay out of one of the 11 types of panels onto a sheets of corrugated plastic - the intersting figure is that the nesting of the panels sheets has been the only hand protocols as a simple traight forward array of the same geometry - this is where it is a hughe gain of time and energy as nesting for so many parts if different would take ages (if even only possible) to find an efficient nested solution...

That starting hypothesis of embeded relative simplicity due to the self-similarity (without even counting the labor time saved to look for the right panels when assembling - imagine a pile of 500 panels to pick from?!!) is RE-questioning the complete mass customization fashion and other kit of parts...

Though the amount of components generated which have to be RE-assembled is also RE-questioning the limit of using generative processes without going further down the line using assembly robots...

Generator.x 2.0: Beyond the Screen

24 Jan - 2 Feb 2008, Ballhaus Naunynstrasse / [DAM] Berlin

Credits:

Design: THEVERYMANY (Marc Fornes + Skylar Tibbits)

Scripting: Marc Fornes

Manufacturing protocols: Marc Fornes + Skylar Tibbits

Laser cutting: Skylar Tibbits

CNC & material research: Jared Laucks

Assembling: Skylar Tibbits (+ helpers!)

ANYONE IN BERLIN INTERESTED TO HELP ASSEMBLING IS HIGHLY WELCOME!!

PLEASE COME OVER AT THE [DAM] GALLERY

(starting on the Jan 29th till February 2nd)

Labels: aperiodic, cnc, digital manuctacturing, generator.x, laser cutting, marius watz, rhinoscript, theverymany